Making New Handles For Construction Chisels

P. Michael Henderson

1/8/2024

I was inspired to make new handles for some construction chisels by an article by Christopher Schwarz. This is how I did it.

I bought a three chisel set of Buck Brothers construction chisels, a 1/4 inch, a 1/2 inch, and a 3/4 inch. Here's the 3/4 inch before conversion.

I used my bandsaw and cut the handle.

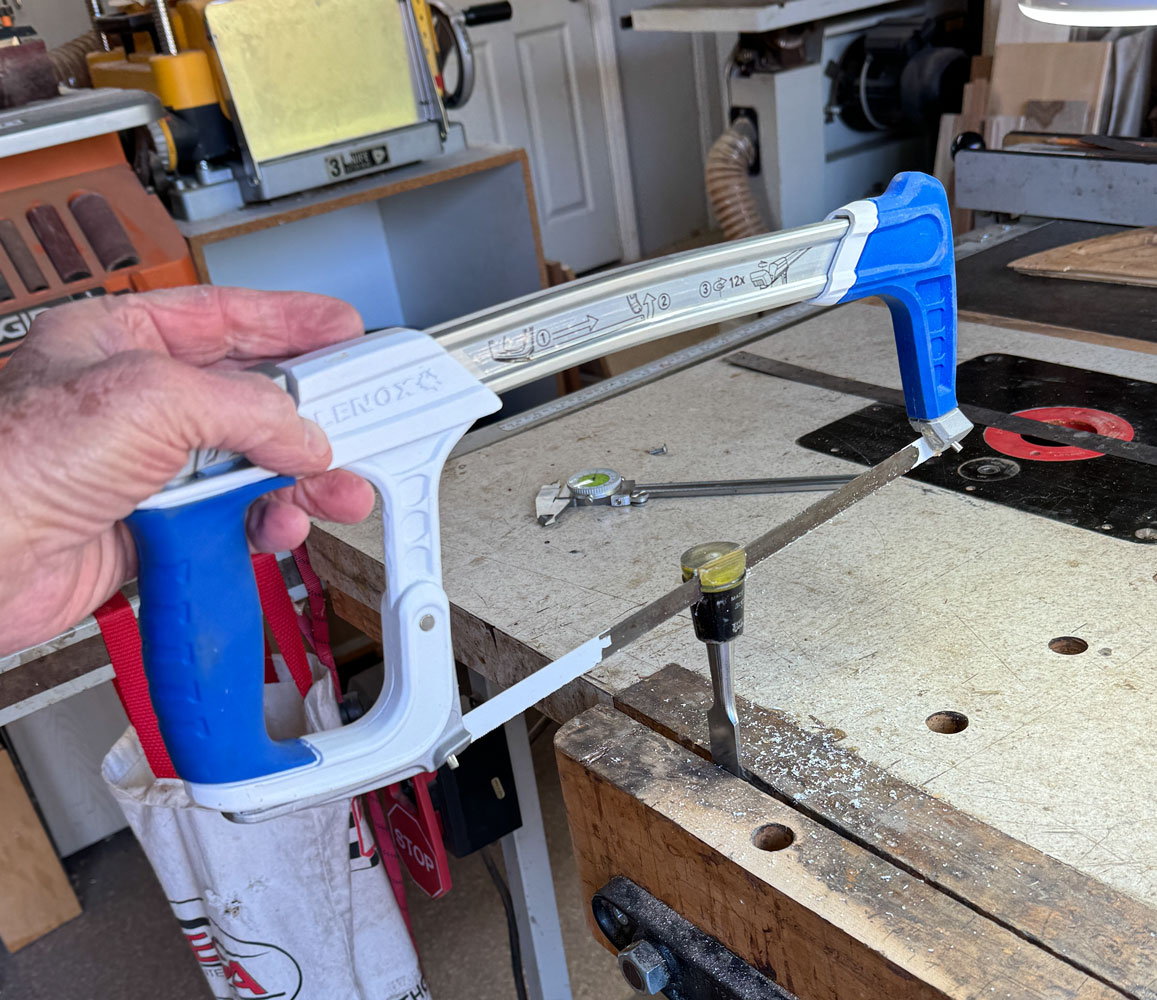

Then I used my hacksaw to cut the handle off.

I cut a bit too close to the tang, but it didn't cause any problems.

Then I used the hacksaw to cut on the other side of the tang and the remaining part of the handle came off. My picture of the tang on the 3/4 inch chisel was out of focus. This is the tang on the 1/4 inch chisel. They were the same size.

I took the chisel to my deburring wheel and cleaned up the tang.

The tang is 5/16 inch in diameter.

I had some maple and cut a piece about 6 inches long and about an inch and a quarter square. I roughed it out on the lathe.

Now, I'm going to drill the hole for the tang. I'm using a 5/16 inch bit and a I mark it with a black marker to indicate how far to drill.

Then drill it on the lathe.

Because this is a tang chisel, I have to use a ferrule on the bottom of the handle to keep the handle from splitting when it is pounded on.

Now I'm going to turn the bottom of the handle to fit the ferrule. Note that now that I have a hole on that end, I have to use a different end on the tail stock, a cone. I mark the length of the ferrule and set a caliper to the diameter of the ferrule.

Then I turn the bottom down to fit the ferrule. I have to go slow because I want a tight fit for the ferrule. I trial fit and turn the ferrule during the trial fit. This leaves a mark where the wood is too high.

When I'm satisfied, I drive the ferrule on with a mallet. I bought these ferrules from Lee Valley many years ago. I don't know if they still sell them.

I drilled the hole and then fit the ferrule, but you can fit the ferrule and then drill the hole, if you want. Both approaches work

Now, I can turn the rest of the handle.

Finally, sand the handle and apply a finish.

Then drive the handle on to the tang. And that's the end of the conversion.

I thought the 6 inch handle was a bit too long, so when I did the 1/2 inch chisel, I made the handle 5 1/2 inches long. You lose part of the handle (for holding) because of the ferrule. Pick a length that works for you.

I still have to do the 1/4 inch chisel.

Click here to go back to my main page.